VOLUM - TRAN

VOLUMetric TRANsformation (VT) relates to the ‘out of box’ approach of the optimization of the volumetric (hydrostatic) machines in order to keep them relevant in the future as it was in the past.

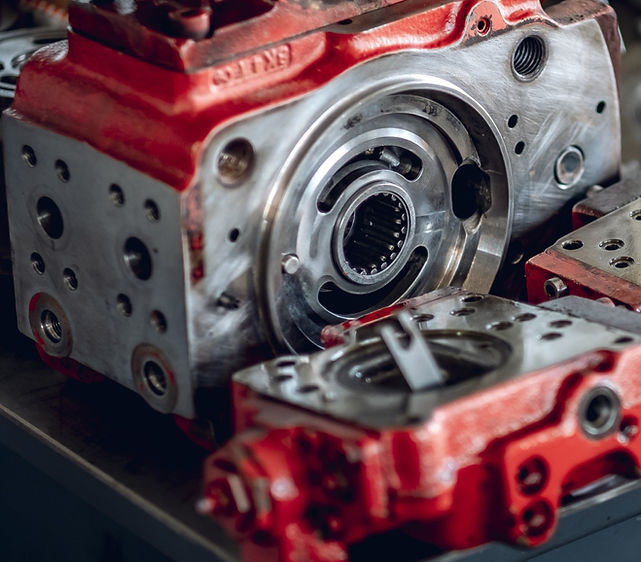

Commercial image of hydrostatic machine

The aim of this approach is to provide cost effective concepts/solutions for the transition toward environmentally friendly vehicles. At present, mentioned transition is dominated by the electro-mechanic solutions, as one presented on the image below.

Commercial image of electromechanical hybrid transmission

SYNERGY

This new, VT approach, is inspired by analysis that showed that synergy between electric and hydrostatic systems, can provide best from two technologies and that is rooted in physics as it is shown below.

Namely for booth; electrics and hydraulics, main losses are related to flow. But, in hydraulics flow is used to generate speed and in electrics flow is used to generate torque. Therefore optimum can be achieved in systems with synergy between electrics and hydraulics where hydraulics is used in low speed / high torque region while electrics is used in high speed low torque region as it is shown in diagram above.

Simple demonstrator of the electrohydraulic transmission was developed in order to show one of advantages over electromechanically transmissions. Namely, as it is shown on video below, developed demonstrator of the electrohydraulic transmission proves that it can work with infinite transmission ration meaning that it is possible to hold output at max torque and 0 speed while electric motor is running at the nominal speed. This can't be achieved with mechanical CVT. On page VT-EVOLUTINO more detail explanation, regarding comparison/advantages between CVT of mechanical and hydraulic type can be found as well as practical implications relating to the advantages of the electrohydraulic CVT. >>

While theoretical advantage of the electrohydraulic CVT transmission is evident, practical realization is limited by the efficiency of the standard hydraulic components, that is lower of the components of the mechanical CVT. Therefore, one aspect of the VOLUM-TRAN project, is to go with 'out of box' approach, i.e. design of the specific hydrostatic machines instead of using standard ones.

This new concepts will allow creation of the advanced electrohydraulic systems but also it will allow creation of the new advanced hydraulic systems that will be competitive as stand alone systems. Increasing number of the applications where those new concepts can be applied unit cost will be reduced.

DIGITAL DISPLACEMENT MACHINES

Radial piston multi-stroke motors/pumps can be designed with independent outputs. When these outputs are assigned displacements that follow a binary sequence — 2⁰, 2¹, 2², 2³ — the result is a digitally controlled variable displacement machine.

In the example shown, a 4-bit digital machine is presented. With just four simple on/off valves, it enables 42 =16 discrete displacement levels ranging from 0% to 100%. In the earlier post, it was mentioned that machines with 3 to 5 bits are a practical choice for considering them as variable displacement machines.

Lower bit values, like 1 or 2 bits, already exist and are best classified as multi-displacement rather than variable displacement, due to the large step size between settings. While machines with more than 5 bits are technically possible — offering finer displacement control — the added complexity may outweigh the benefit for most industrial applications.

MAC-MPROVEMENT OF THE AXIAL PISTON MACHINES

One of the important aspects of the electrohydraulic components, needed to bring success of the VT approach is to strive for higher efficiency as it will allow to perform same work with smaller batteries. One of the studies that were considered are improved axial piston machines named Machines of Axial Compact (MAC) design. One important characteristic of this design is lateral piston hydrostatic lubrification controlled by the piston rod inclination as it is shown on image below. Pumps based on this design will allow conversion of the mechanical into the hydraulically energy with improved efficiency. Purpose of this presentation is to underline 'out of box' approach, namely more advanced concepts are under development at moment...

VDMSM-MPROVEMENT OF RADIAL PISTON MACHINES

As the axial piston machines are good option for high speed low torque transmission components, radial piston multi-stroke machines are good/best options for the low speed high torque transmission components

Radial piston multi-stroke motor is important hydrostatic machine as it allows creation of the direct drives, without backlash, unprecedently smooth torque and all that with high overall efficiency. Drawback of existing designs is related to the fact that they are unable to provide continues variation of the displacement meaning that they can't provide energy efficient functions as traction control and/or regenerative breaking that it important feature when reduced CO2 emission is imperative for new machines. Providing variable displacement option, for radial piston multi-stroke machines creates new opportunities for this type of the high performance technology in addition to hydrostatic modulation, already mentioned. More about state of the advancement of this concept can be found on page >>

HYDROSTATIC MODULATION - IMPROVEMENT OF THE CLUTCHES

Clutches are important part of the advanced transmissions, either when they are used to activate disactivate certain systems, either when they are used in torque modulation. Problem with clutches, especially when they are used for torque modulation, is energy loss generated by the friction between discs. In ordered to suppress/reduce energy loss associated with standard clutches new device is proposed Hydrostatic Modulator where friction between clutches is replaced by the piston action on to the cup cam...

HYDRAULIC BATTERY - IMPROVEMENT OF THE HYDRAULIC ENERGY STORAGE

One of the interesting aspects, to go with electrohydraulic, is energy storage. Namely even new batteries made significant improvement their major advantage is in capacity of energy that can be stored. On other side hydraulic accumulators are very poor in terms of energy amount that can be stored. On contrary in terms of the power that can be delivered and stored hydraulic accumulators are more capable than electric batteries. Therefore in electrohydraulic transmission batteries will be used to store energy needed to provide radius like Zero Emission Vehicle (ZEV) while hydraulic accumulators can/will be used to deliver burst of power during acceleration and store the energy during breaking.

This means that batteries for the electrohydraulic transmission, don't have to made compromise between energy storage et power as energy storage will be managed by the batteries while power bursts can/will be managed by hydraulic accumulators.

In order to improve packaging new concept of the hydraulic accumulators is proposed; As they are intended to be used a side of the electric batteries this new concept is named Hydraulic battery. In this innovative design, of the hydraulic accumulators, high pressure accumulator is integrated into the low pressure accumulator. Shape of the high pressure accumulator is set by physics and it is of circular shape. On other side shape of the low pressure accumulator can be of the rectangular shape allowing significant reduction of the integration volume. Difference between standard design, with separate high and low pressure accumulators, and new design, with integrated high and low pressure is presented by schematically on image below.

All rights reserved (Tous droits réservés). All statements on this website are solely personal view of the author, provided as general information only.

More details can be find on page